Picking the Right Seal

Deciding on just the right seal for your application can be complicated, as there are many factors that need to be considered. This introduction to those factors will provide insight to assist you in coming up with the perfect seal that gets the job done.

First, what is the seal meant to do? There are as many applications for rubber and plastic seals as there are profiles to choose from.

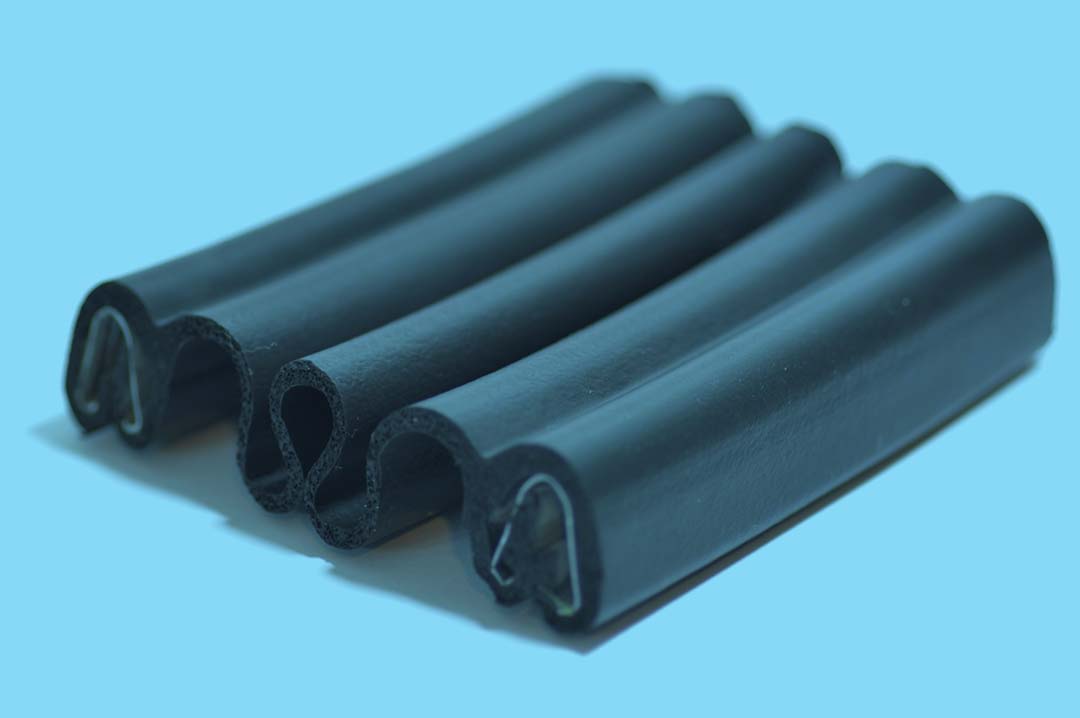

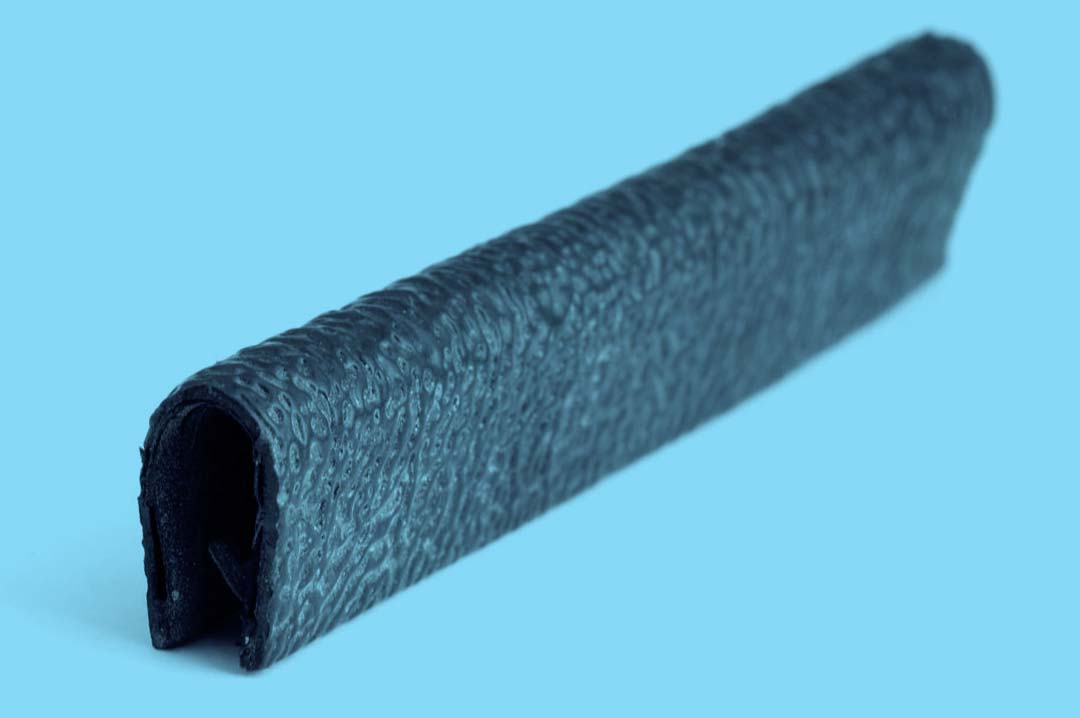

Edge Trim

If you are looking to cover an unfinished or sharp edge on steel or fiberglass, then a plastic or rubber edge trim may do the trick. These profiles have a steel interior and an outside made of extruded plastic or rubber. The steel interior is what gives it the clamping power to help it stay on the application, while the outside material gives it a nice finished look. The steel interior is flexible which allows it to be applied around radiuses and not buckle or widen at the opening.

Click this link for more information about edge trim.

Click this link for a selection of just some of our edge trim designs.

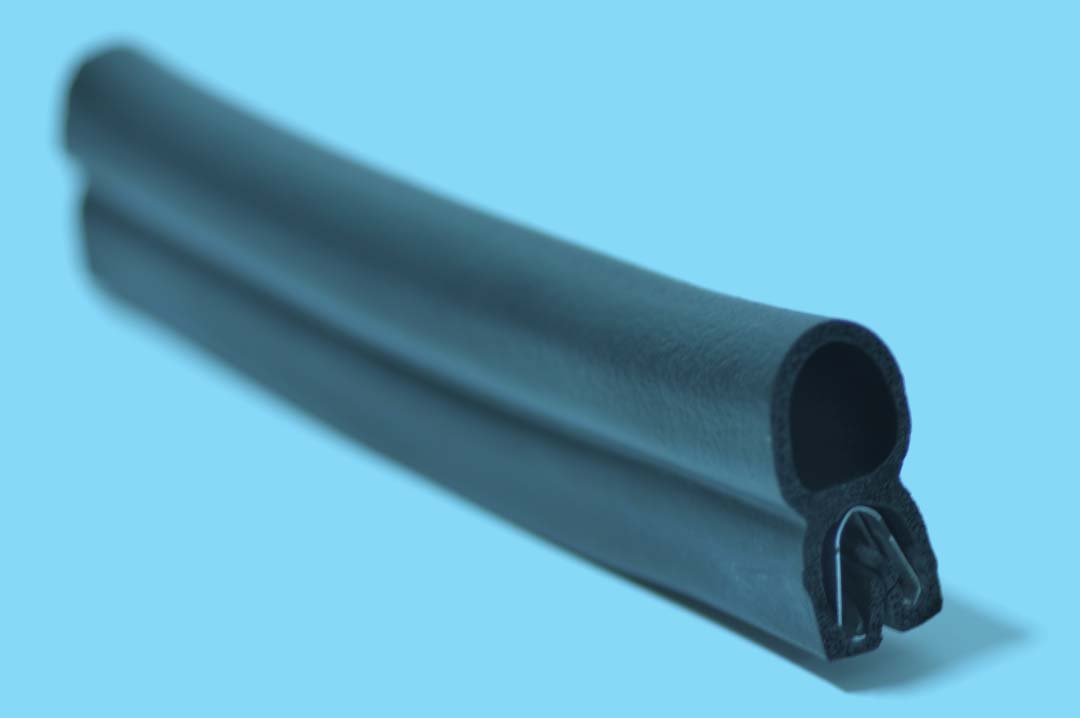

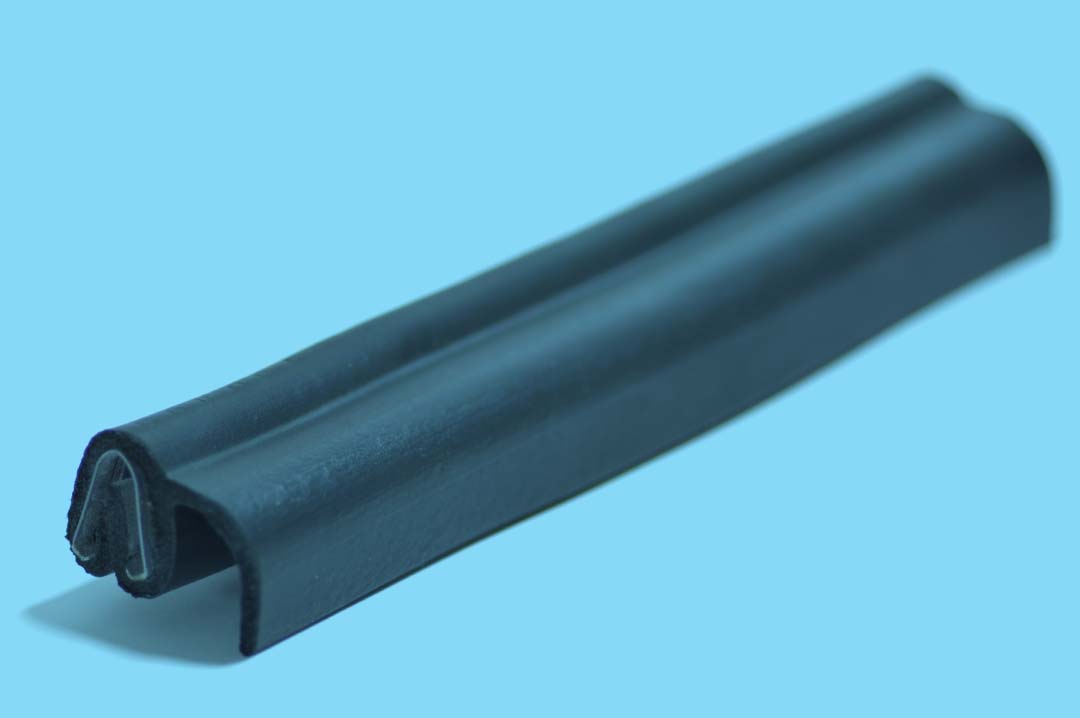

Bulb Seals

Edge trims can have the added feature of a bulb, either glued-on or even produced as one profile in a process called co-extrusion. Both methods allow the profile to act as a seal commonly used for compartments or doors with a flange to attach the profile.

Click this link for more information about selecting the right bulb seal.

Also, check out just some of our bulb seals.

Flap Seals

Flap seals can be used to wipe moisture away from applications that can get wet or to divert moisture away from areas that need to stay dry. These seals can be fastened with clips like an edge trim or applied with tape.

At this link, we will discuss the different types of tape.

Also, check out just some of our flap seals.

Application Specific Seals

The above general categories of seals can be used in many different applications. There are also seals that are very application specific, and are designed to solve a specific problem:

Window Gaskets

These seals are specifically designed to lock in a window on a truck or trailer or anywhere a window would be used. It has two sides to it, one to fasten onto the flange and the other to lock in the glass. This is a two-part system with a smaller piece that is inserted into the seal to lock the two openings tight. This is made from a dense rubber compound in order to create a solid seal with the least amount of wiggle room on the flange or glass.

Slide-Out Seals

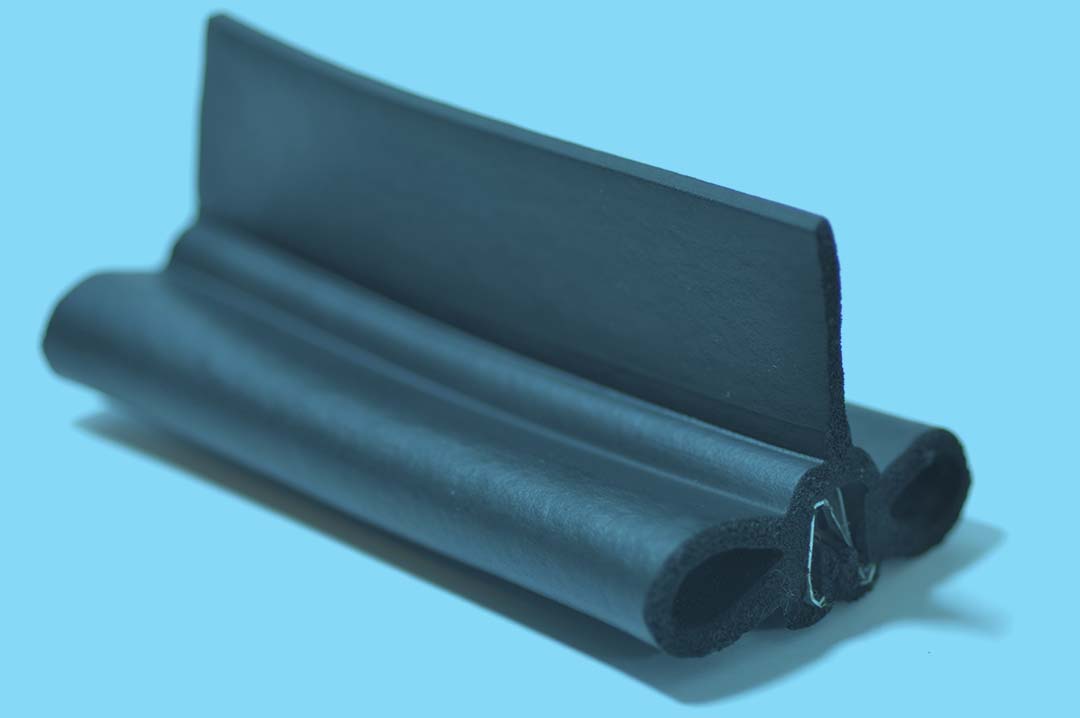

Slide-out seals are specially designed to create a soft seal on a slide-out room against a recreational vehicle (RV) and guard against water finding its way into the vehicle. We offer two main classes of slide-out seals for the RV market. One requires a flange on the RV for insertion, the other is applied with tape. We have several options that use the clip-on flange fastening system: ED-50468-T, ED-50465 and the ED-50474. Each one has slightly different features, but all include a combination of bulbs and flaps.

We also have a slide-out seal system that doesn't require a flange and is applied with 3-M heat activated tape (HAT). This new patent-pending slide-out seal system is called the Uni-Seal. The Uni-Seal system includes three different types of seals for the outside, bottom and interior of the slide-out unit. The patent pending technology allows for a bulb to be pulled away for applying a mechanical fastener like a staple or screw and then the bulb will snap back to the original position. It is a one-piece slide-out seal design that is effective, can be efficiently installed, is shipped by the coil in a box and works with most RV designs.

Click this link to see our selection of slide-out seals.

Also check out our new website devoted to recreational vehicle slide-out seals...slideoutseals.com

Accordion Seals

These are very specialized seals that are designed to cover large dynamic gaps with a significant range of motion. With ranges from one to fifteen inches of coverage, these seals will protect gaps from the elements and stay clipped on with our strong spring steel clips. These seals can be found on emergency vehicles, trucks with sleeper cabs or anywhere else a dynamic expandable seal would be needed.

Our spring steel is inserted into the rubber seal to create a strong clip-on action that can be used on a flange for a strong connection that will not lose its clamping power over time (even when removed and reinstalled). The seal is made from durable, long lasting rubber.

Follow this link to see our full range of accordion seals.

And Much More!

These are just a few of the variations and applications of seals available. We have over 600 different seals that we produce for our customers, and offer a variety of secondary processes. Cut-to-length, Normec splicing, gluing, Vulcanized corners, tape, inserting steel, slip coat, etc. save valuable time at application.

There are other design considerations that need to be factored in such as sponge vs dense, material properties, tape types, cold and hot splicing, etc. We will cover all of these factors in other articles.

We do all our design and tooling in-house and can make just about any profile you can dream up, so put our group to the test and give us a call.